LOAD-DEQ (Multi Loading Online Control Stability System)

1. Base module "Intact Trim & Stability"

This software is a Windows application and has multi-windows, standard controls and interaction with other Windows applications. It was designed for calculating and controlling trim and stability of an intact vessel.

All data you put in through interactive windows, the results of full calculation are displayed in graphic and tabular form. The parameters' limits, as specified by the Classification Society and IMO, are shown on the right side from the calculated values. Some criteria are always displayed as a Brief Result.

Loading conditions can be taken from and stored in the archive.

Shearing Forces and Bending Moments are determined by sum of weights (weight moments) for Light weight and Dead weight and buoyancy forces of the part of the vessels aft from the considered section.

This information is given in graphic (diagram of share forces and bending moment) and in table form. The calculated values will be compared with acceptable stress as calculated for the intact vessel.

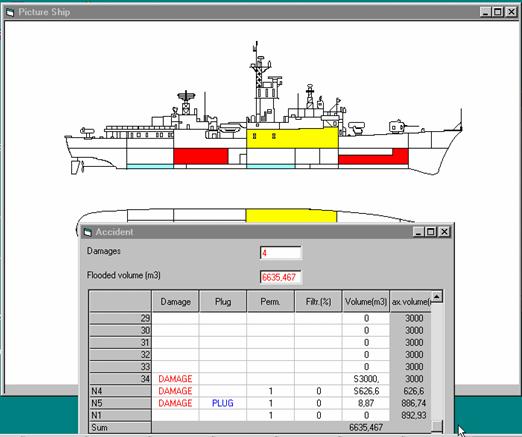

The module allows to estimate the condition of a damaged vessel for any combination of flooded compartments including: compartments open to the sea and compartments which are not open to the sea but are partly filled with water.

Damage stability parameters: Minimum Free Board (minimum depth of the freeboard); Flooded Water (a total volume of water which entered the damaged compartments); Reserve buoyancy (a total volume of intact compartments above the equilibrium waterline).

This module allows to input and store information about container cargo and creating a container cargo plan through interactive mode.

It is possible to load the containers from a container database to the selected bay by using the mouse cursor or keyboard and to see some useful information about each container. Various tools are allowing to create container lists.

Container in different colours are shown in the display for easy identification as the colours are directly related to the port of destination. Any groups of containers can be formed and located manually but will be marked by groups.

This module is giving the opportunity for interactive operations inside information tables of appropriated groups of tanks to create and to edit a liquid cargo plan consisting of: ballast water, fuel oils,lub oils, liquid cargo (especially for oil- and chemical tankers), miscellaneous liquids (fresh and technical water, feed water, thermal oil and other).

The tank tables are worksheets providing general information of the tanks and consists of a number of columns as: TANKS, Max. Volume, Volume, Percent, Weight, Level, Density. Some of them are passive and cannot be accessed (e.g., Max. Volume). In Simulation mode the operator can enter anyone of the characteristics like: volume, volume %, weight, density or level. Upon completion all other values will be re-calculated.

In case data of the tanks content are obtained from a level measuring system (in ONLINE mode), editing of this tank data will be blocked. After input of data for liquids volume and density, the weight and percentage of filling are calculated automatically assuming that the level was measured with zero heel and zero trim. In ONLINE mode the correction of tank volume and weight value is possible by using a heel and trim measuring system.

The menu-string allows also automatic filling of tanks on 100 %, 50 % or dry.

This module is giving the opportunity for interactive operations inside information tables to create and to edit a bulk cargo plan.

The worksheet provides full information on the holds and consists of a number of columns as: HOLDS, Max.Volume, Volume, Percent, Weight, Level, Stw Fuct., LCG, VCG. Some of them are passive and cannot be accessed (e.g., Max.Volume).

Summary of weights of bulk cargo in the holds listed is also indicated.

The operator can enter any of the following characteristics: Volume, Volume(%), Weight, Level. The others will be recalculated depending on the bulk cargo Storage factor.

Additional input for grain:

This module is designed to create a general cargo plan.

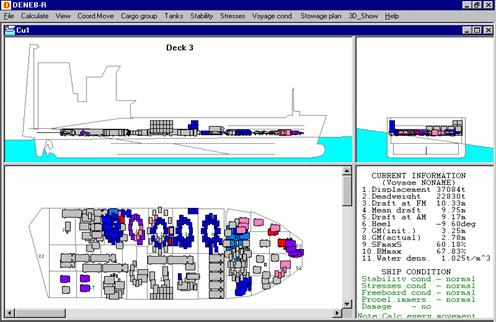

All cargo spaces are represented in three projections. Each cargo is shown with it's colour (port sign). Explanation of the colour is given in the window together with the ID-code of the item.

There is a function to review various decks or cross-sections as: Plan - selecting horizontal plane which is parallel to main deck or selected deck; Cross section - the section which is parallel to the transverse section, Side view - the section which is parallel to the longitudinal section. This option is very useful for any vessels transporting oversized heavy-weight cargoes like tanks, docks or platforms etc., when the detailed consideration of any premises and equipment is required. It gives the possibilities to get a complete three-dimensional analysis of the hold space.

Cargo can be moved by mouse or by vessels co-ordinates to a selected place.

The additional main menu functions: Optimise, Show, Data base are specially designed for the use of the interactive cargo location inside of "complicate" vessels (type ro-flow), to position vessels inside a floating dock or transport heavy equipment with floating platforms. For example, Show-function can show an animation regime of a deck with cargoes or a floating dock with ships inside or as a floating platform with cargo. It can be analyzed how to construct or filling particular spaces of the floating object.